Automated Vertical Farming 2026: The Tech Stack Behind Scalable Agriculture

The agricultural revolution of the 2020s wasn’t fought with tractors or combines; it was fought with code, sensors, and robotics. As we move deeper into 2026, the concept of automated vertical farming has graduated from a novelty investment to a critical component of the global food security supply chain. For AgTech founders and investors, the question is no longer “can we grow food indoors?” but “can we do it profitably at scale?”

The answer lies entirely in the technology stack. The vertical farms that are thriving today are those that have successfully transitioned from being “farms with computers” to “technology companies that produce food.” This distinction is vital. It dictates capital allocation, hiring strategy, and ultimately, unit economics.

In this deep dive, we will explore the architecture of a winning automated vertical farming operation in 2026. We will look at the convergence of AI, IoT, and robotics, and specifically examine how Willo Farm leveraged a consumer-facing digital platform to revolutionize the subscription model. Whether you are a pre-seed founder or a Series B operator, this guide provides the roadmap for building a scalable, fundable AgTech business.

The Evolution of Controlled Environment Agriculture (CEA) and Automated Vertical Farming

Controlled Environment Agriculture (CEA) has always been about optimization. However, the definition of “optimization” has shifted dramatically. In the early days, it was about extending growing seasons. Today, it is about precise molecular control of plant development when it comes to automated vertical farming.

From Hydroponics to “Computed Growth”

Traditional hydroponics provided roots with nutrient-rich water. Modern automated vertical farming provides plants with a calculated environment where every variable—light spectrum, humidity, air velocity, CO2 concentration, and root zone temperature—is a data point governed by an algorithm.

This shift to “computed growth” means that a modern farm looks less like a greenhouse and more like a high-performance data center. The plants are the servers, and the harvest is the output. But just like a data center, if your cooling fails or your load balancing is off, the system crashes. In agriculture, a “crash” means crop loss, broken contracts, and burned capital. The stakes are incredibly high, and the margin for error is non-existent.

The Role of Software in 2026

In 2026, software is the primary driver of yield. We are seeing a move away from generic “farm management software” towards bespoke, integrated operating systems that handle everything from seed inventory to last-mile delivery. This is where the competitive advantage is built. Hardware is often commoditized; you can buy LED lights and racking systems from multiple vendors. But the *brain* of your farm—the software that orchestrates those lights to mimic a Tuscan summer for your basil crop—that is proprietary value.

The Core Tech Stack: Hardware, Software, and Biology for Automated Vertical Farming

To understand automated vertical farming, we must dissect the stack. A scalable AgTech operation stands on three pillars: The Physical Layer (Hardware), The Cognitive Layer (Software/AI), and The Biological Layer (Plant Science).

1. The Physical Layer: Robotics and IoT

The physical layer is where the digital meets the biological. In 2026, this layer is defined by density and autonomy.

Internet of Things (IoT) Sensor Grid

You cannot automate what you cannot measure. A high-performance vertical farm is a dense grid of sensors. We are no longer satisfied with one temperature sensor per room. We are seeing micro-climatic sensing at the rack or even tray level.

- Spectral Sensors: Monitoring the exact light spectrum reaching the canopy.

- Root Zone Sensors: Measuring Dissolved Oxygen (DO), pH, and Electrical Conductivity (EC) in real-time.

- Visual Sensors: High-resolution cameras and multispectral imaging for plant health monitoring.

- Airflow Sensors: Detecting stagnant microclimates that promote fungal growth.

Robotics and Material Handling

Labor has historically been the silent killer of vertical farming profitability. Automation solves this.

- Automated Guided Vehicles (AGVs): Moving trays from germination to growth zones without human touch.

- Robotic Seeding and Harvesting: High-speed, sterile end-effectors that plant and harvest with millimeter precision.

- Cleaning Bots: Ensuring sterility between cycles to prevent pathogen outbreaks.

2. The Cognitive Layer: AI and Data Processing

This is the “Brain” of the operation. All data from the IoT layer flows here to be processed.

Predictive Analytics

It is not enough to know that humidity is high. You need to know that humidity *will be* high in 30 minutes because the HVAC cycle is out of sync with the transpiration rate of the crop. AI models predict these fluctuations and adjust the environment proactively.

Computer Vision for Phenotyping

Cameras constantly scan the crops. Computer vision algorithms identify tip burn, nutrient deficiencies, or pest pressure days before the human eye could catch it. This allows for micro-interventions—adjusting the nutrient mix for just one specific zones—rather than broad, wasteful corrections.

3. The Biological Layer: Digital Genetics

In 2026, we are breeding seeds specifically for vertical farming. These “indoor seeds” are designed for compact potting, rapid growth cycles, and specific light recipes. The software tracks the performance of different genetic batches, creating a feedback loop that informs future seed selection.

Real-World Proof: How Willo Farm Revolutionized the Subscription Model in Automated Vertical Farming

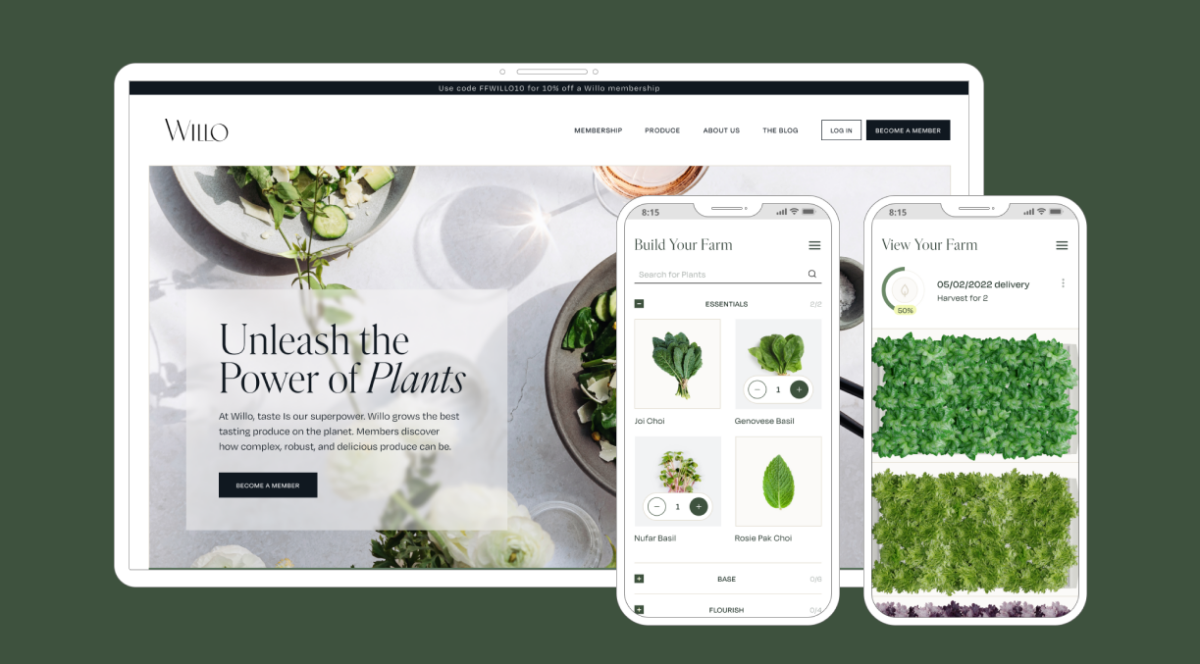

Theory is useful, but execution is everything. To see automated vertical farming in action, we look to Willo Farm, a pioneer in the space that partnered with Presta to build their digital infrastructure.

The Challenge: Connecting the Farm to the Consumer

Willo Farm wasn’t just growing leafy greens; they were selling a relationship with the farm. Their business model was a direct-to-consumer (D2C) subscription where members could choose their crops and monitor their growth. They needed a platform that could:

- Visualize the Farm: Allow users to “see” their personal plot.

- Manage Subscriptions: Handle complex, customizable delivery schedules.

- Integrate Operations: Connect the front-end user choice with the back-end farm logistics.

The Solution: A Salesforce-Integrated Digital Platform

Presta worked with Willo to create a seamless web application that served as the digital twin of their physical farm.

- User Experience: We designed a “Select Your Farm” interface where users could drag and drop crops—Tuscan Kale, Arugula, Bok Choy—into their virtual slots. This wasn’t just a shopping cart; it was a farm management tool for the consumer.

- Salesforce Integration: The backend was heavily integrated with Salesforce. every crop selected by a user became a “order” for the farm’s operating system. This bridged the gap between “what the user wants” and “what the farm needs to plant.”

- Transparency: Users could track the status of their plants from “Seed” to “Harvest” to “Delivery,” creating a level of engagement that standard grocery delivery services could never match.

The Outcome

The result was the world’s first true “Farm-to-Front-Door” digital experience. By automating the customer management and order logic, Willo could focus on what they did best: growing incredible produce. This case study illustrates a critical lesson for 2026: Your digital product is as important as your agricultural product.

The 4-Stage AgTech Maturity Model for Automated Vertical Farming

For founders looking to build or scale an automated vertical farming startup, it is helpful to view the journey through a maturity model. Where is your startup on this curve?

Phase 1: The Manual Prototype (Seed Stage)

At this stage, you are validating unit economics and crop recipes.

- Technology: Off-the-shelf sensors, manual data logging (Excel/Google Sheets), basic environmental controllers.

- Operations: High labor input. Founders are often “in the racks.”

- Goal: Prove you can grow a high-quality product consistently.

Phase 2: The Connected Farm (Series A)

You have validated the product; now you need data visibility.

- Technology: Centralized dashboarding (e.g., Ignition SCADA), integrated IoT sensors, basic alerts for failures.

- Operations: Labor is still manual, but directed by data. You know when to water, even if you still turn the valve manually.

- Goal: Gather enough data to train future AI models.

Phase 3: The Automated Operator (Series B)

This is the shift to robotics and partial autonomy.

- Technology: Automated material handling (conveyors/AGVs), proprietary farm OS, integrations with ERP systems (like NetSuite or Salesforce).

- Operations: Labor shifts from “farming” to “maintenance” of machines.

- Goal: Reduce OpEx and increase throughput.

Phase 4: The Autonomous Biosystem (Scale/Exit)

The farm runs itself.

- Technology: AI-driven closed-loop control (the system adjusts itself without human approval), end-to-end robotics from seed to pack.

- Operations: Skeleton crew of engineers and biologists. The software manages the P&L of the crop.

- Goal: Maximum margin and replicability across new locations.

Unit Economics of Vertical Farms: The Code to Profitability for Automated Vertical Farming

The most common reason vertical farms fail is broken unit economics. Capital expenditure (CapEx) is high, so Operating Expenditure (OpEx) must be ruthlessly minimized. Automated vertical farming is the only way to achieve this.

Breaking Down the Cost Structure

- Energy (25-30%): LED lights and HVAC are power-hungry. Automation helps by managing “Day/Night” cycles to align with cheaper electricity rates (peak shaving) and optimizing LED duty cycles.

- Labor (40-50% in manual farms -> <15% in automated farms): This is the game-changer. A manual farm needs scouting, cleaning, seeding, transplanting, and harvesting crews. An automated farm needs a maintenance tech and a software engineer.

- Depreciation (CapEx): Automation increases upfront CapEx but drastically extends the lifetime of equipment by operating it within optimal parameters.

The Role of Custom Software in Margin Expansion

Off-the-shelf software charges you per user or per sensor. As you scale, these costs balloon. Building your own “Farm OS”—or partnering with a studio like Presta to build it—turns a variable cost into a fixed asset. This increases the valuation of your company (you own IP) and stabilizes your monthly burn.

Designing Your MVP with a Strategic Partner

Navigating the complexities of automated vertical farming requires more than just theory, it requires execution. Book a discovery call with Presta to discuss how our Startup Studio can help you build the digital infrastructure for your farm while minimizing risk and maximizing ROI. Whether you need a customer-facing subscription platform like Willo or a backend yield-prediction engine, we build the systems that make AgTech fundable.

Strategic Framework: Implementing Automation Without Breaking the Bank for Automated Vertical Farming

How do you move from a manual operation to a fully automated one without running out of cash? Follow this implementation framework.

Stage 1: The “Digital Twin” Assessment

Before you buy a single robot, map your entire process digitally.

- Action: Use process mapping software to document every human touchpoint.

- Output: A heatmap of where labor hours are consumed. Usually, this is transplanting and harvesting.

Stage 2: The “Low Hanging Fruit” Retrofit

Automate the high-frequency, low-dexterity tasks first.

- Action: Install automated irrigation dosing and climate control. These are mature technologies with immediate ROI.

- Output: 24/7 consistency in crop environment, removing human error from the most critical variable.

Stage 3: The Data Backbone Construction

Build the software layer that effectively “catches” the data you are about to generate.

- Action: Implement a centralized data warehouse. Ensure all sensors speak a common language (e.g., MQTT).

- Output: A single source of truth for farm performance.

Stage 4: The Robotic Integration

Now, and only now, do you introduce heavy robotics.

- Action: Deploy automated seeding and harvesting lines.

- Output: Massive reduction in labor headcount and potential increase in contamination control.

Validation Checklist for AgTech Software and Automated Vertical Farming

If you are building or buying software for your farm, ensure it passes this validation checklist:

- Interoperability: Can it pull data from your HVAC (BacNet), your Lights (DALI), and your specialized sensors (API)?

- Offline Mode: If the internet cuts out, does the farm keep running? (Edge computing is non-negotiable).

- Scalability: Can it handle 10x the data volume when you open your second facility?

- User Agency: Does it empower your growers or confuse them? (UX is critical in high-stress environments).

- Financial Integration: Does crop waste automatically write off inventory in your ERP?

Measuring Success: KPIs and Proof Points for Automated Vertical Farming

You cannot manage what you do not measure. In automated vertical farming, your KPIs must go beyond “yield per square foot.”

What to Expect 30-90 Days Post-Automation

When you implement a robust automation and software layer, here is the trajectory:

Days 0-30: The “Calibration” Phase

- Metric: Sensor Uptime and Data Integrity.

- Expectation: You will find that your old manual readings were wrong. You will spend this month calibrating your sensors and setting baseline “truth.”

- Win: You finally know what is actually happening in your grow room 24/7.

Days 30-60: The “Stabilization” Phase

- Metric: Climate Stability (Standard Deviation of Temp/Humidity).

- Expectation: The automated systems begin to tighten the control loops. The “sawtooth” pattern of manual control flattens into a steady line.

- Win: Plant stress events drop by >50%.

Days 60-90: The “Optimization” Phase

- Metric: Grams per Watt (g/W) and Labor Hours per Kg.

- Expectation: You begin to see yield increases due to stability. More importantly, your labor costs drop as the team trusts the system.

- Win: Unit economics begin to align with your pro forma.

Frequently Asked Questions

What represents the highest cost in automated vertical farming?

Energy and labor are the two primary cost centers. While automation significantly drastically reduces labor costs (often by 70% or more), energy consumption for HVAC and LED lighting remains the dominant operational expense. However, advanced automation helps mitigate this via smart energy management, such as load shifting and predictive climate control to prevent energy waste.

How does AI differ from standard automation in farming?

Standard automation follows a set script: “If temperature > 25°C, turn on AC.” AI, specifically machine learning, is predictive and adaptive: “Based on the weather forecast and current crop transpiration rates, the temperature *will* rise in 30 minutes, so I will precool the room now to save energy.” AI learns from past cycles to optimize future ones; automation just repeats instructions.

Is vertical farming actually sustainable?

It depends on the energy source. A vertical farm powered by coal is not sustainable due to high energy density. However, a vertical farm powered by renewable energy (solar/wind/hydro) is incredibly sustainable. It uses 95% less water than traditional farming, requires zero pesticides, eliminates fertilizer runoff (preventing algae blooms), and reduces food miles by locating production near cities.

Can I retrofit an existing farm with automation?

Yes, but it is often more expensive than building Greenfield. Retrofitting requires working around existing constraints—column spacing, ceiling heights, amperage limits—that may prevent the use of optimal robotics. However, “Digital Retrofits”—adding sensors and better software to existing hardware—is a very high ROI activity that every existing manual farm should undertake immediately.

Why did Willo Farm choose a subscription model?

The subscription model provides predictable recurring revenue (ARR), which is highly attractive to investors and allows for better demand planning. In traditional farming, you grow and then hope to sell. In a subscription model, like Willo’s, you essentially sell before you grow. This drastically reduces food waste and inventory risk, creating a much more efficient business cycle.

Do I need a technical co-founder to start a vertical farm?

In 2026? Absolutely. You are starting a tech company. If you do not have a technical co-founder, you must partner with a venture builder or a specialized product agency like Presta. You cannot rely on third-party vendors to glue your entire tech stack together; you need someone who understands the architecture of your data and your digital product.

How do I fund a vertical farming startup in 2026?

Investors in 2026 are “hardware shy” and “Ops heavy.” They want to see fundable startups that have solved the unit economics problem. They are looking for intellectual property (IP) in software or genetics, not just a warehouse full of kale. To raise capital, focus on your “Capital Efficiency” and your path to positive cash flow, rather than just massive expansion plans. Show them you can operate one facility profitably before you ask for money to build ten.